Researchers at Northwestern University’s McCormick School of Engineering have developed a novel resin-based 3D printer that offers exceptional print speed and excellent part accuracy.

In a unique representation, the system combines photopolymerization with a six-axis robotic arm that may be used by an industrial DED 3D printer or a traditional assembly line. With the freedom to move, rotate and re-scale every layer during construction, the machine also grants a completely new level of design freedom.

Cheng Sun, Associate Professor of Mechanical Engineering at Northwestern University and lead author on the project, said, “The 3D printing process is no longer a way of just creating a replica of the model being designed. Now we have a dynamic process where all the layers are put together using light, but with a great deal of freedom to move each layer along the way. “

Northwestern’s novel 3D printer uses a six-axis robotic arm. Image via Northwestern University.

A new version of model cutting

When working with traditional planar 3D printers, the software used to create models cuts an object into flat horizontal planes. Hence, these layers can be stacked on top of each other to replicate the STL file in the real world. The northwest approach turns this on its head, replacing the sequential layered approach with a more fluid continuous process.

Since the printer’s robot arm is not exclusively arranged in the Z-axis, it can be used to dynamically transform each shift on the fly and to swivel the printing direction without having to stop or restart printing. Since the printing machine is a DLP-based light projector, the overall system is also suitable for fast curing times and high-resolution functions. Entire layers are 3D printed at once and there is no delay between layers, so the system is continuously rolling.

Sun adds, “We use light for manufacturing. When the liquid polymer is illuminated, it crosslinks or polymerizes and converts the liquid to a solid. This contributes to the speed and precision of our 3D printing process – two major challenges that conventional 3D printing faces. “

2,000 shifts per minute

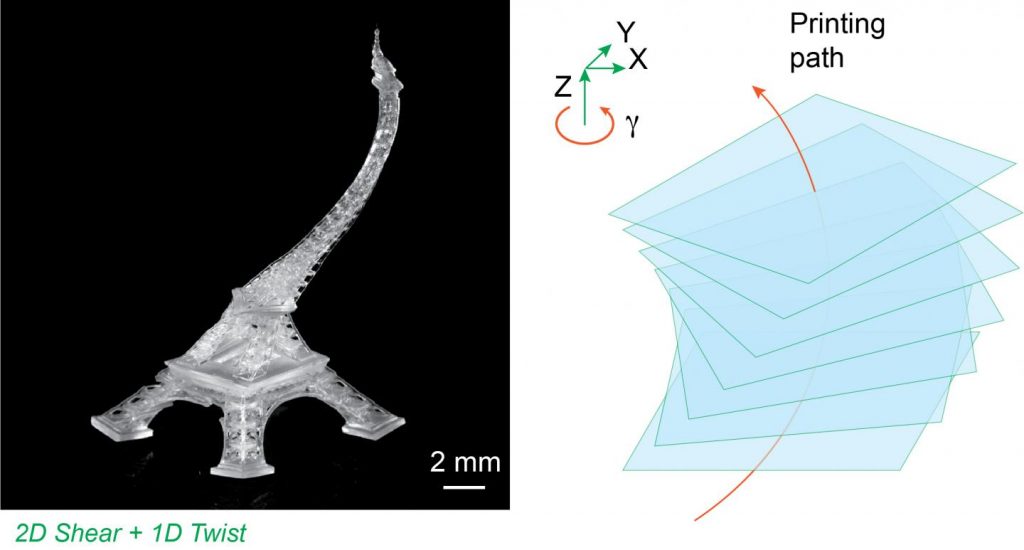

Looking at the numbers, the continuous process can print around 2,000 layers per minute. Researchers demonstrated the capabilities of the system by making a series of test prints, including an Eiffel Tower, a double helix, and a highly custom vascular stent. Because the 3D printer is also compatible with multi-material constructions, the team was able to create a soft pneumatic gripper with a rigid base and soft actuators that paved the way for a new method of fast part manufacturing.

Sun summarizes, “This is a very quick process and there is no break between shifts. We hope that manufacturing will benefit from this. The general printing process is compatible with a wide variety of materials. “

Further details on the 3D printer can be found in the article “Conformal geometry and additive manufacturing from multiple materials through freeform transformation of building layers”. It was developed by Cheng Sun et al.

The development of high-speed 3D printing systems is not limited to the experimental limits of a research laboratory. Optical systems maker, In-Vision, marketed its own high performance DLP hardware and recently launched its most powerful 3D printing light engine to date. HELIOS was developed over the course of two years and is a UV light projector which was specially developed for resin-based 3D printing systems and is intended to achieve the highest illuminance on the market.

Elsewhere, the OEM UpNano 3D printer previously upgraded its two-photon polymerization system with high-powered lasers to improve its printing speeds. The laser, combined with the company’s patented adaptive resolution technology, enabled the company’s NanoOne printing system to produce high-precision parts with nanoscale resolutions.

Subscribe to the 3D printing industry newsletter for the latest news on additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Print Jobs for a selection of roles in the industry.

The image shown shows a dynamically transformed Eiffel Tower printed on the Northwestern 3D printer. Photo via Northwestern University.