Image supplied.

Image supplied.

A groundbreaking development in aerospace construction is underway in Melbourne with the launch of Australia’s first multi-metal 3D printer as part of the iLAuNCH Trailblazer initiative, according to a media release.

The aim of this cutting-edge technology is to make space missions more cost-effective and efficient by producing lighter, faster and longer-lasting Aerospace Components.

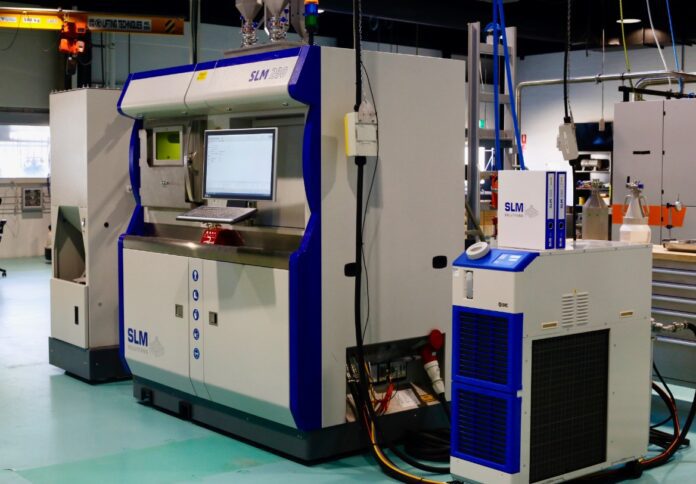

The Nikon SLM-280 (Selective Laser Melting) is housed in CSIROs The Lab22 facility will revolutionize manufacturing by printing metals side by side in a single continuous process.

This advancement is particularly well-suited to aerospace applications that require high-performance, lightweight materials, giving engineers the freedom to design components that are both structurally efficient and cost-effective.

Dr. Joni Sytsma, Chief Technology Officer of iLAuNCH trailblazerwas excited about the potential of this groundbreaking technology.

“This capability is the first of its kind in Australia and the Southern Hemisphere. iLAuNCH is pleased to open new manufacturing opportunities for locally manufactured aerospace products.”

The introduction of this multi-metal 3D printer is expected to give Australian companies involved in satellite and rocket manufacturing a competitive advantage.

By optimizing designs and streamlining production processes from their Melbourne base, these companies can increase performance while reducing lead times and costs.

In addition, the technology shows potential for producing new superalloys that can withstand extremely high temperatures, essential for the further development of hypersonic air transport.

The printer’s ability to produce complex geometries in a single process also has significant implications for other industries, including automotive racing, where lightweight, high-strength components are essential.

Dr. Cherry Chen, senior research scientist at CSIRO, highlighted the multi-metal 3D printer’s wide range of applications, including satellite structures, novel radiation shields and high-performance heat exchangers.

“Other applications to be considered include satellite structures and components, as well as the development of novel alloy radiation shields being developed in the various laboratories under the iLAuNCH Trailblazer,” noted Dr. Chen.

The multi-metal version of the SLM-280 is a significant improvement over its standard counterpart, a model that has already gained international recognition for its versatility and performance.

Notable achievements include the creation of a monolithic thrust chamber for a rocket propulsion engine with a unique lattice structure in collaboration with CellCore GmbH, an engineering firm based in Berlin; the development of a hydraulic valve block in collaboration with the VTT Technical Research Center of Finland, resulting in a remarkable size reduction of 66% and a weight reduction of 76%; and the production of a gooseneck mount with ASCO, a Belgian aerospace company, achieving a significant reduction in the buy-to-fly ratio from 17 to 1.5 and a weight reduction of 31%.

Donald Godfrey, global director of business development for aerospace and defense at Nikon SLM Solutions, highlighted the shift in metal joining technology, noting that traditional methods such as hot isostatic pressure (HIP) or welding and brazing of dissimilar metals have been prevalent for decades.

“The delivery of laser powder bed fusion technology to create a truly functionally graded material component to CSIRO is the first time the technology has been brought out of Germany. “This technology sets a new foundation for what is possible in the aerospace industry,” said Godfrey.