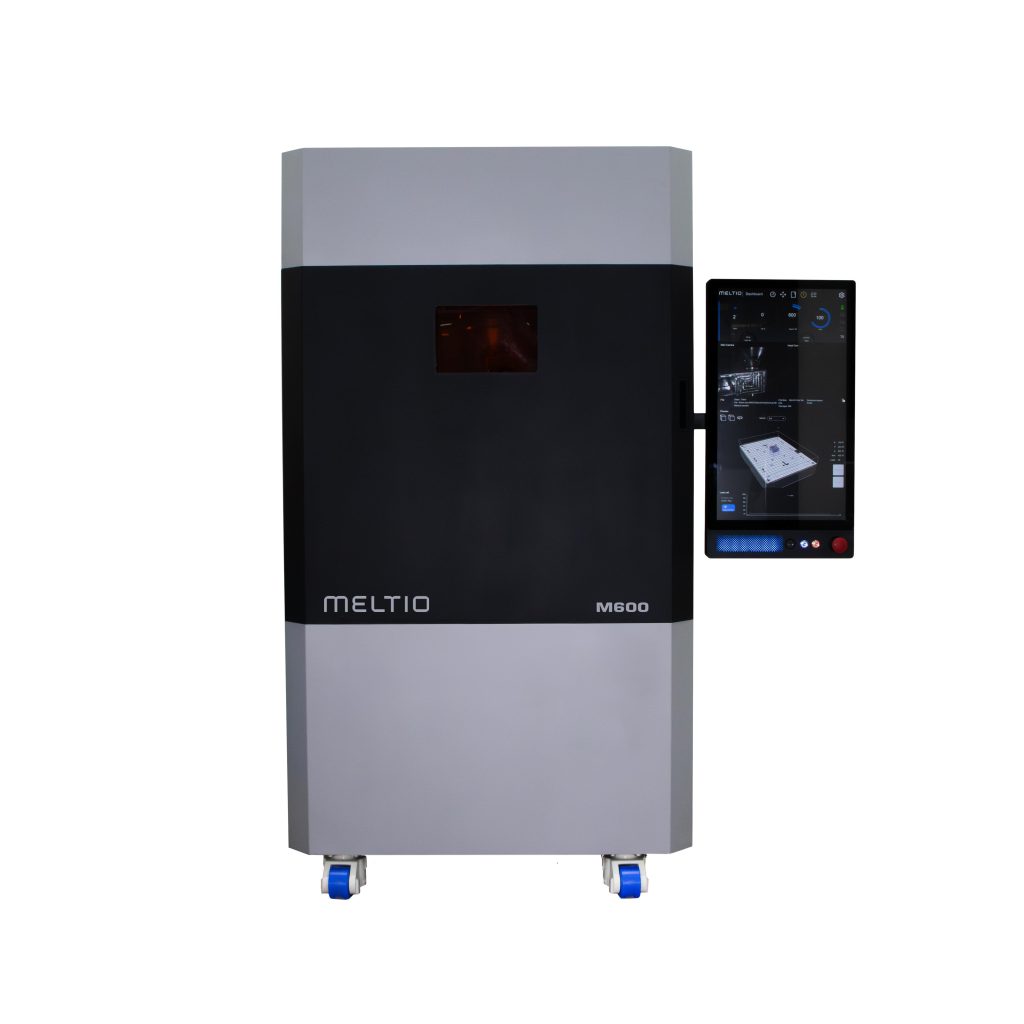

Metal 3D printer developer Meltio has introduced the M600, its latest laser metal deposition (LMD) 3D printer, at the 2024 Additive Manufacturing Users Group (AMUG) conference currently taking place in Chicago, Illinois.

Equipped with a newly developed blue laser deposition head, the 3D printer is designed for industrial-scale manufacturing and optimized for machine shops and other 24/7 production environments.

According to Meltio, the M600 was designed to overcome manufacturing challenges associated with long lead times, costly warehousing and supply chain uncertainties.

“The design brief for the new Meltio M600 was to imagine what the perfect 3D printer for the machine shop would look like,” explained Lukas Hoppe, Meltio’s head of research and development.

“The vast majority of 3D printed metal parts require post-processing that is performed in the machine shop, and as our goal is to drive large-scale adoption of metal additive manufacturing, we have a very clear vision that the modern machine shop is the ideal entry point .”

The 3D printer’s autonomous production capabilities minimize the need for manual user input. This enables 24-hour non-stop production operations, increasing productivity and reducing manufacturing costs. In addition to 3D printing metal parts, this new system can add functionality to existing components and repair damaged surfaces.

The Meltio M600 is compatible with a range of materials including aluminum and copper alloys, titanium, stainless steels, tool steels, nickel, Invar and Inconel.

Spanish cement company Cementos La Cruz has been announced as the first customer to adopt Meltio’s new 3D printer. The company used the M600 to 3D print a stainless steel nozzle for producing more sustainable, additively manufactured cement structures.

The new metal 3D printer Meltio M600. Image via Meltio.

The new metal 3D printer Meltio M600. Image via Meltio.

Meltios new M600 wire laser 3D printer

According to Hoppe, the M600 is intended to further Meltio’s mission to increase the adoption of metal additive manufacturing. He believes metal 3D printing has not yet reached its full potential because the technology is still largely limited to small-batch production of high-value parts.

The new 3D printer uses welding wire as the raw material. These materials are much cheaper and safer to handle than their powder-based counterparts, making the M600 easier to integrate into existing manufacturing workflows.

With a sizeable build volume of 300mm x 400 x 600mm, Meltio claims that its new 3D printer’s wire-laser deposition process can produce high-quality parts with comparable material properties to those made using more conventional methods.

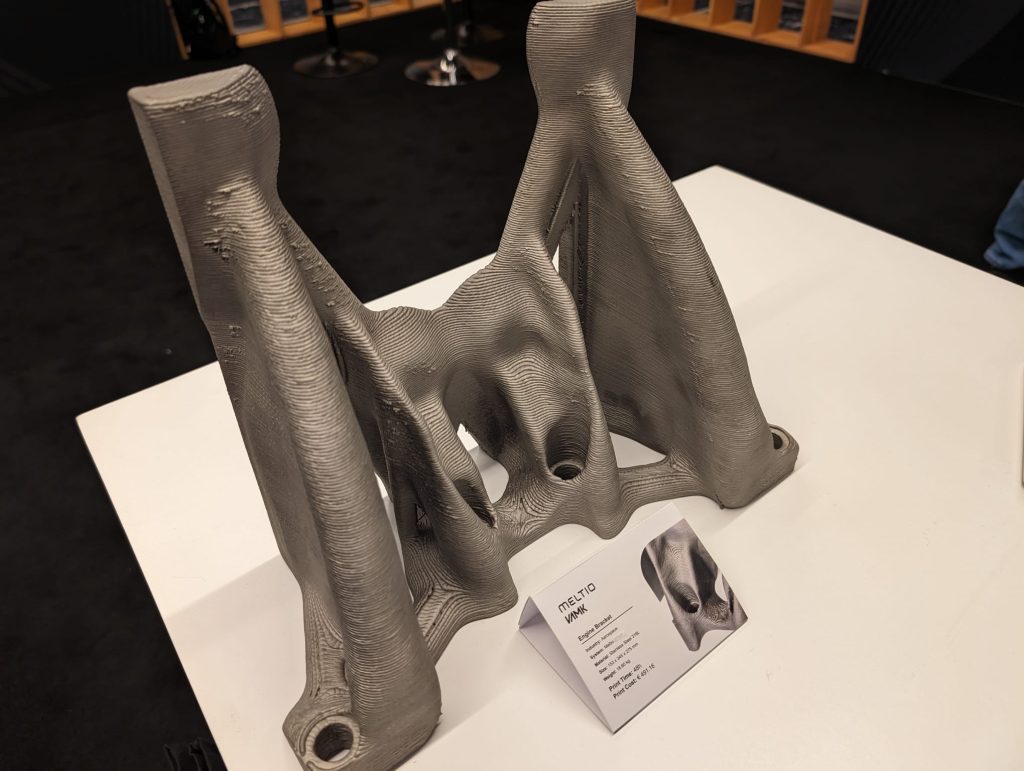

3D printed motor mount featuring the Meltio M600 on display at AMUG 2024. Photo by 3D Printing Industry.

3D printed motor mount featuring the Meltio M600 on display at AMUG 2024. Photo by 3D Printing Industry.

The M600’s blue laser deposition head enables faster 3D printing speeds with lower energy consumption thanks to the lasers’ short light wavelength. This provides higher absorption compared to most industrial lasers that emit near infrared (NIR) light, while reducing the carbon footprint of the production setup.

The blue lasers are particularly suitable for reflective materials such as copper and aluminum alloys, where NIR lasers often produce poor results.

Meltio has worked to improve power distribution and wire routing, ensuring that the deposition head is properly aligned before leaving the factory floor and cannot be adjusted by the user. This reduces maintenance and allows for more consistent output. Reliability is also improved through the use of sensors that monitor the entire 3D printing process.

The Meltio M600 is also designed to integrate into industrial environments with existing CNC machines. With a built-in 3-axis touch probe, the system supports various workpiece types. Therefore, in addition to 3D printing, Meltio’s new offering can also be used to repair or add functions to existing metal parts.

As a highly autonomous system, the M600 requires very little operator intervention. Common inputs such as manual laser alignment have been completely removed. Meltio says this will increase the reliability and productivity of the 3D printer, which is designed for light-free manufacturing. Meltio Horizon toolpath generation and slicing software is also compatible with the M600, allowing 3D printing jobs to be prepared in minutes.

3D printed DM combustion chamber with the new Meltio M600 on display at AMUG 2024. Photo by 3D Printing Industry.

3D printed DM combustion chamber with the new Meltio M600 on display at AMUG 2024. Photo by 3D Printing Industry.

Meltio announces first M600 customer

With the M600, Meltio has sought to create a 3D printer that can be integrated into any machine shop and works with existing CNC hardware.

The company claims its new 3D printer delivers remarkable value by reducing material waste, shortening lead times, increasing manufacturing flexibility and completing complex 3D printing jobs with minimal operator effort. This is said to make the M600 well-suited to a variety of industrial sectors, including automotive, aerospace, oil and gas, mining, defense and construction.

The Meltio M600’s first publicly announced customer falls into the latter of these categories. Cementos La Cruz focuses on producing cementitious materials with a low carbon footprint. The company focuses on leveraging a circular economy and also develops specific 3D printing technology for construction applications in its 3DLAB.

3D printing with concrete requires a high level of control of the material flow. To achieve this, the company used the Meltio M600 to 3D print a nozzle that can produce high-quality layers of extruded concrete. According to Meltio, the M600 has enabled Cementos La Cruz to design and produce parts that would not be possible using traditional manufacturing methods.

Cemento’s La Cruz nozzle 3D printed with the new Meltio M600. Photo via Meltio.

Cemento’s La Cruz nozzle 3D printed with the new Meltio M600. Photo via Meltio.

Technical data of the Meltio M600

Meltio has not yet released pricing information for its new M600 3D printer.

| Dimensions | 1050mm x 1150mm x 1950mm |

| Create cover | 300mm x 400mm x 600mm |

| Weight | 1000kg |

| movement system | Servo motor linear axis with absolute encoder on all axes |

| Filter system | 3-stage particle and chemical filtration included |

| Environmental control | Control O2 and humidity levels |

| Laser type | 9x direct diode laser |

| Laser wavelength | 450 nm |

| Total laser strength | 1,000W |

| Total axes | 3 |

| Process control | Closed loop, laser and wire modulation |

| Touch probe | Automated XYZ touch probe integration |

| Enclosure | Laser safe, completely inert |

| cooling | Active water-cooled radiator included |

| Diameter of wire material | 0.7mm – 1.2mm |

| Wire supply spool | BS300 or external wire drum |

What does the future of 3D printing look like?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to stay up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page and subscribe to the 3D Printing Industry YouTube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available positions and boost your career.

The image shows a large 3D printed glass mold using the new Meltio M600, exhibited at AMUG 2024. Photo by 3D Printing Industry.