Photo credit: ESA

Photo credit: ESA

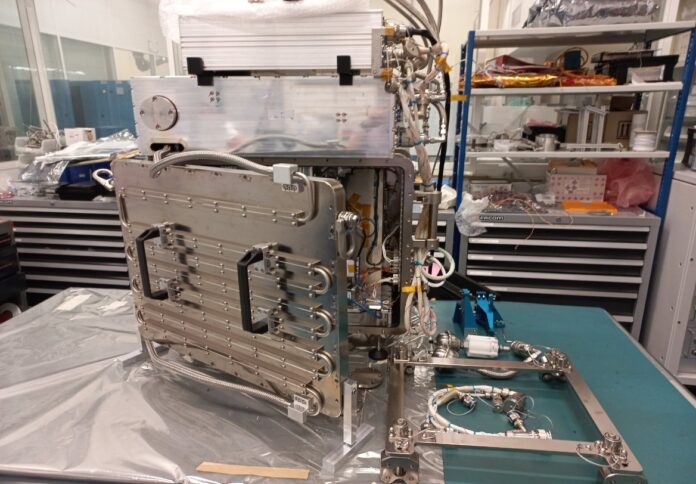

The European Space Agency (ESA) has brought the first metal 3D printer to the International Space Station (ISS).

The cutting-edge technology, part of the Cygnus NG-20 resupply mission, aims to revolutionize manufacturing in space by enabling the production of metal parts in the microgravity environment of space, ESA said said in a press release.

“This new 3D printer, which prints metal parts, represents a world first at a time of growing interest in manufacturing in space,” said Rob Postema, ESA’s technical director.

He explained that polymer-based 3D printers using plastic materials have already been deployed on the ISS, but metal printing opens up new possibilities for strength, conductivity and rigidity in space-based structures.

The metal 3D printer was developed by an industrial team led by Airbus Defense and Space SAS and is a collaboration with ESA’s Manned and Robotic Exploration Directorate.

Patrick Crescent, Project Manager at Airbus, emphasized the importance of this in-orbit demonstration, saying: “It paves the way for the production of more complex metal structures in space. This is a crucial advantage for the safe exploration of the Moon and Mars.”

The 180 kg metal 3D printer will be installed in the European Draw Rack Mark II in ESA’s Columbus module by ESA astronaut Andreas Mogensen upon his arrival on the ISS.

The printer is powered by stainless steel wire, which is commonly used for medical implants and water treatment due to its corrosion resistance.

A high-power laser, a million times more powerful than your average laser pointer, heats the wire to create metal imprints.

The technology demonstrator will undergo a series of tests that will print four specially selected shapes that will be compared to reference prints on Earth.

These shapes, smaller than a soda can, will be analyzed for differences in print quality and performance in the space environment.

As part of ESA’s goal of creating a circular space economy, the 3D printer could play a crucial role in recycling materials in orbit and reusing them for new tools or structures.

This innovation eliminates the need to send pre-built tools onto rockets, allowing astronauts to print the necessary parts directly in space.

Tommaso Ghidini, head of ESA’s mechanical department, sees Metal 3D printing as a promising capability to support future exploration activities and contribute to more sustainable space practices.

“Metal 3D in space printing is a promising opportunity to support future exploration activities, but also beyond that to contribute to more sustainable space activities, through in-situ fabrication, repair and potentially recycling of space structures for a wide range of applications,” he explained.

Ghidini continued: “This includes the manufacture and assembly of large-scale infrastructure in orbit, as well as the long-term colonization of the planet by humans. These aspects are key focuses of ESA’s upcoming cross-technology initiatives.”

Thomas Rohr, head of ESA’s Materials and Processes Division, added: “This technology demonstration, demonstrating the processing of metallic materials in microgravity, paves the way for future efforts to produce infrastructure beyond Earth’s boundaries.”