Austrian ceramic 3D printing specialist Lithoz has announced a significant 30% increase in 3D printer sales compared to 2022, while increasing material production.

According to Lithoz’s report, the company has reaffirmed its global market leadership in 3D ceramic printing, highlighting strong sales performance. In 2023, Lithoz’s focus was to launch the “Ceramic AM Factory,” which uses lithography-based ceramic manufacturing (LCM) 3D printers for mass industrial production. According to Lithoz, most of the machines were sold to partners with multiple Lithoz 3D printers, underscoring the significant role of serial production in the company’s results in 2023.

“By building these interconnected machine parks, Lithoz is driving the growth of series production in ceramic 3D printing,” said Dr. Johannes Homa, CEO of Lithoz. “We consistently work with our customers to achieve mass production. With one of our partners now producing well over a million parts per year, it’s fantastic to see how all the effort is paying off!”

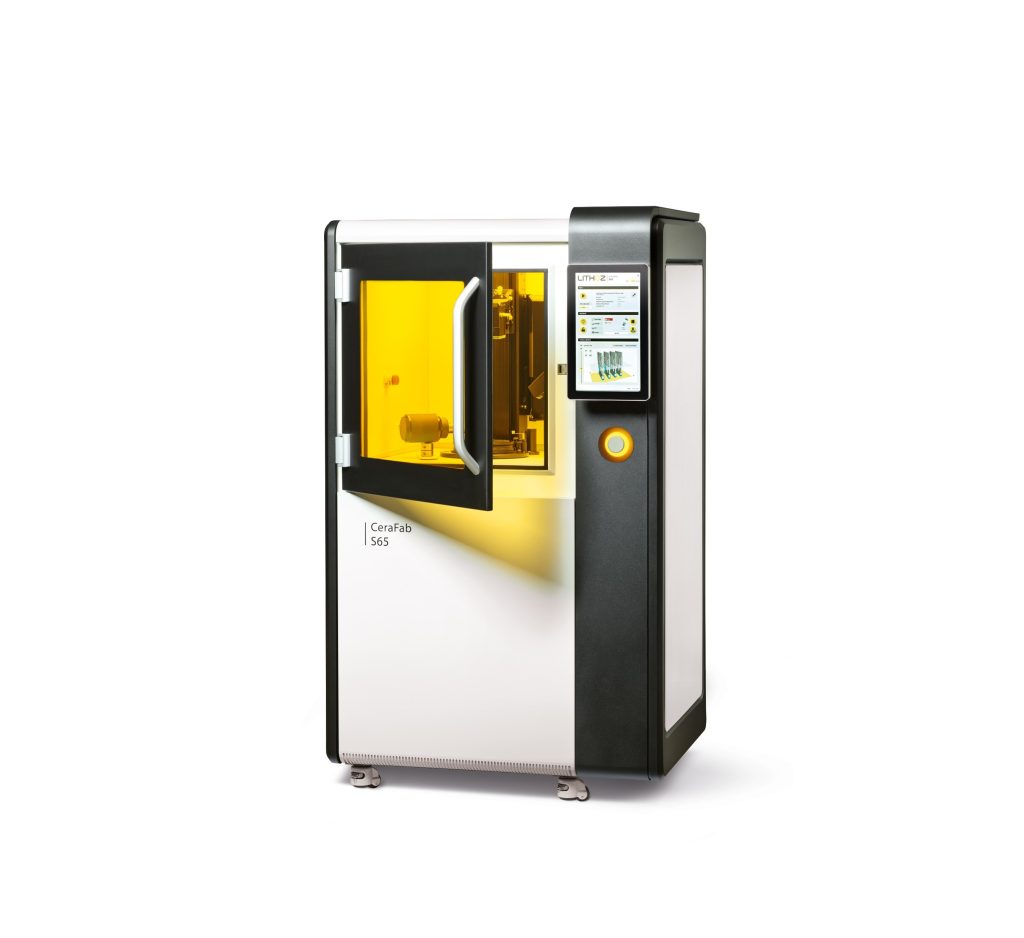

Lithoz CeraFab S65. Photo via Lithoz.

Lithoz CeraFab S65. Photo via Lithoz.

Lithoz’s comprehensive 3D printing technologies

Lithoz’s LCM technology exceeds metal limits in harsh conditions and has demonstrated advances in 3D printing with advanced ceramics in the aerospace sector. The CeraFab S65 with LCM enables precise 3D printing of ceramic casting cores for aircraft turbine blades, reducing development time. Its multi-material 3D printers improve efficiency and enable tailored porosity and complex designs. Lithoz’s expanded production shows the potential for aerospace components such as ceramic RF filters and silicon nitride aerospike nozzles.

In addition to emphasizing series production, Lithoz strategically developed a comprehensive 3D ceramic printing portfolio and consolidated various aspects of the technology. According to the company, investments in Laser-Induced Slipcasting (LIS) technology, LSD printing and multi-material manufacturing via AMAREA Technology contributed to Lithoz’s positive performance in 2023.

Last December, Lithoz and the U.S. Department of Energy’s Oak Ridge National Laboratory (ORNL) collaborated in a cooperative R&D agreement focused on Lithoz’s 3D printing technology for non-oxide ceramics. The Lithoz CeraMax Vario V900 3D printer utilizes LIS technology and utilizes laser slurry drying to achieve precise mesh forming.

This project sought to improve high refractive index non-oxide ceramics, such as silicon carbide, intended for extreme temperature applications. The aim was to industrialize the production of ultra-high temperature ceramic parts with a thorough material performance evaluation for aerospace applications.

Looking ahead to 2024, Lithoz has outlined plans to support the growth of 3D ceramic printing by expanding the number and capacity of service offices worldwide. The company’s goal is to build machine parks and expand its offering of 3D printed ceramic solutions to further expand Ceramic AM Factory’s capabilities for mass production in series and drive innovation in industrial applications.

Lithoz company logo. Image via Lithoz.

Lithoz company logo. Image via Lithoz.

What does the future of 3D printing look like in the next ten years?

What technical challenges will need to be overcome in the field of additive manufacturing in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D printing industry newsletter, follow us on Twitter or like our page on Facebook.

While you’re here, why not subscribe to our YouTube channel? With discussion, debriefings, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Under 3D printing jobs you will find a selection of positions in the industry.

The picture shown shows Lithoz CeraFab S65. Photo via Lithoz.