Hylo 3D printer. Photo credit, all images: AON3D

AON3D (Montreal, Quebec, Canada), a North American manufacturer of industrial 3D printers and software, introduces Hylo, a new “smart” high-temperature 3D printer, and Basis, an additive manufacturing (AM) software that uses process simulation and machine is equipped with learning-controlled thermal optimization and part qualification tools. Together, the two solutions simplify and accelerate the process of printing freely available materials, carbon fiber composites and high-performance polymers – materials with greater specific strength than many metals, continuous use temperatures of up to 260°C, extreme chemical resistance and more.

Hylo is capable of using chopped carbon, glass and Kevlar fiber reinforcements. Notably, the company says it also prints with carbon fiber-reinforced polyetheretherketone (PEEK), supported by Hylo and Basis’s use of process simulation and automation to integrate material awareness into the cutting process.

With a 25.6″ × 17.7″ × With a 17.7-inch build area, a 250°C chamber, and over eight times the throughput, Hylo delivers print speeds of up to 500 mm/s and IDEX-ready duplication/support modes. Beyond its specifications, the 3D printer features advanced process control and monitoring through thermal optimization software. Equipped with more than 25 integrated sensors, Hylo produces reliable, accurate and stable parts from commercially available materials by continuously monitoring, controlling and compensating for process fluctuations.

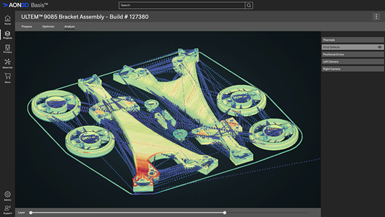

A digital twin of a 3D printed part shows an area of a print that began to warp. Including warpage, AON3D’s foundation allows manufacturers to detect and prevent defects such as cracks, over/under extrusion, thermal fluctuations, internal defects, dross/debris inclusions and more.

The basis is the foundation of AON3D’s new product ecosystem. Intelligent hardware combines with intelligent slicing and in-process monitoring, turning process variability into part safety with just a few clicks. Although full details have not yet been released, AON3D Basis adds material-specific thermal awareness to the cutting process, dynamically adjusting process parameters to optimize properties such as layer weld strength, dimensional accuracy, surface finish and more.

In addition, AON3D Basis users can quickly check the quality of printed parts by viewing Hylo’s process monitoring data in three dimensions. AON3D’s quality control tool also captures deformation/cracks, over/under extrusion, filament diameter variations, hidden defects, slag/debris inclusions, and other important features.