During Formnext 2023, the French 3D printer manufacturer presented Qualup SAS introduced its latest FDM 3D printer, the Qu4-HT.

This new 3D printer features an adaptive build chamber that automatically adjusts to the height of the part during the 3D printing process. This function is intended to significantly shorten the heating times of the build chamber and speed up the 3D printing process.

After the company released its first heated chamber 3D printer back in 2014, the Qu4-HT is the fourth generation system following the introduction of the Qu3-HT last year. While the Qu3-HT has a similar adaptive build chamber, it has a smaller build volume of 300 x 250 x 300 mm compared to 400 x 400 x 360 mm for the Qu4-HT.

The new 3D printer from Qualup SAS is scheduled to be commercially available in January 2024. The price is currently between $75,000 and $90,000 depending on optional add-ons.

At Formnext, 3D Printing Industry spoke with Qualup owner and technical manager Philippe Boichut to find out more about the Qu4-HT.

Qualup’s new Qu4-HT 3D printer at Formnext 2023. Photo by 3D Printing Industry.

Qualup’s new Qu4-HT 3D printer at Formnext 2023. Photo by 3D Printing Industry.

Key features of the Qu4-HT

The heart of the Qu4-HT is its adaptive bellows-style build chamber that automatically expands during the 3D printing process. According to Boichut, this allows the build chamber to be quickly heated to the required temperature, reducing downtime and increasing productivity.

“You save a lot of time when heating,” explains Boichut. “We can heat the chamber to 245℃ in less than ten minutes.” According to Boichut, no other 3D printer on the market can achieve these heating speeds with equivalent 3D printing volume. Additionally, thanks to the adaptive build chamber, the build plate is held in place by a vacuum, allowing users to quickly and easily remove the build plate at the end of the 3D printing process.

Boichut also explained that “the airflow in the build chamber is perfect, so you get a better part.” In fact, the Qu4-HT’s laminar, highly ventilated AirFlow 3D printing chamber ensures a constant flow of hot air throughout the entire 3D printing area, renewing itself almost twice per second. This is to ensure perfect thermal uniformity and prevent overheating and deformation of the parts.

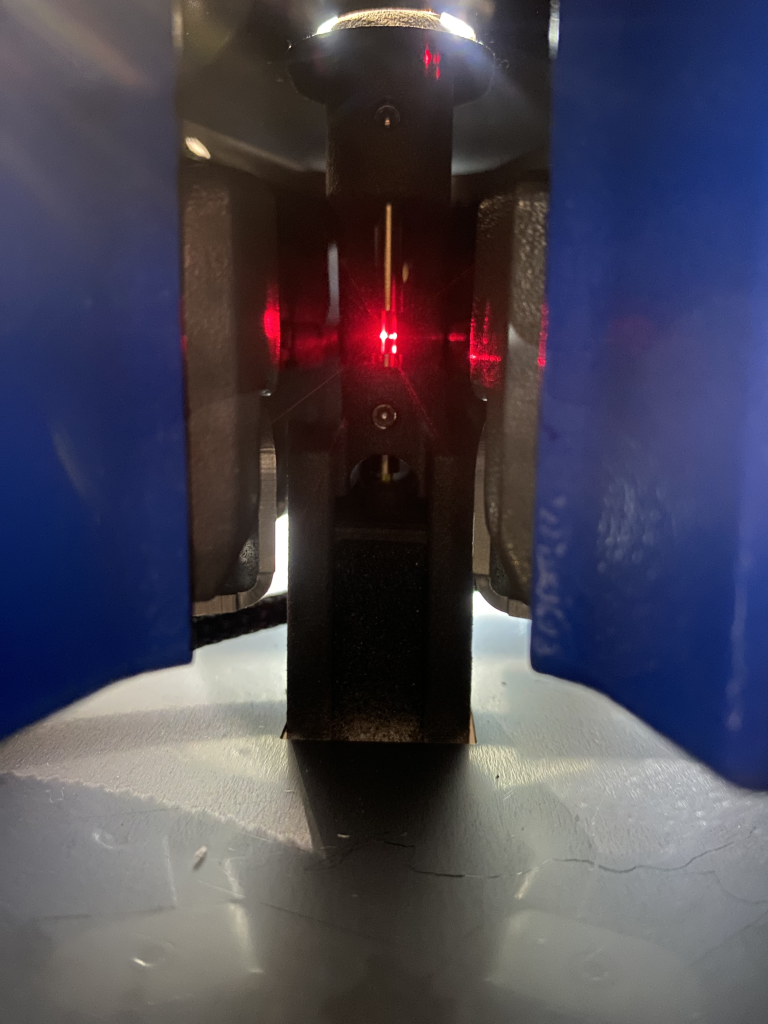

The retracted build chamber of the Qu4-HT. Photo by 3D Printing Industry

The retracted build chamber of the Qu4-HT. Photo by 3D Printing Industry

The maximum 3D printing chamber temperature of the Qu4-HT is 300°C, with the heated chamber also able to heat treat parts at the end of the 3D printing cycle. Therefore, Qualup SAS’ new offering is compatible with a range of high-performance materials including PEKK, PPSU, PI and PEI.

The Qu4-HT is also equipped with PEEK, PEI, metal and glass 3D printing beds, further optimizing the 3D printer for use with a range of high-performance materials at various temperatures. Qualup SAS also provides STEP CAD files of the 3D printing bed upon request, allowing users to develop their own 3D printing beds.

Boichut emphasized that the Qu4-HT is aimed at customers in “large-scale industry,” including the automotive sector.

Material compatibility of the Qu4-HT from Qualup. Photo by 3D Printing Industry.

Material compatibility of the Qu4-HT from Qualup. Photo by 3D Printing Industry.

The Qu4-HT also offers interchangeable printhead functions so that single extruders, dual extruders or pellet extruders can be added to the 3D printer. A change in extrusion technology can be accomplished in just ten minutes, allowing for a high level of flexibility and adaptability.

The Qu4-HT printheads, controlled by technology from Duet3D, can be heated up to 490°C and are liquid cooled, pumping 500 liters of liquid per hour through the printhead. The coolant itself is cooled by a fan, ensuring that the liquid never exceeds 45°C at extrusion temperatures of 420°C.

Qualup also offers its QuControl filament quality assurance system as an optional add-on for the Qu4-HT. This system continuously measures the filament diameter during 3D printing and compensates for deviations in real time.

“We have filament quality control on the back of the machine,” Boichut explained. “Filament can often vary by +/- 0.05 mm, resulting in a 12% volume variation between the maximum and minimum tolerance.” According to Boichut, QuControl offers significant improvements in the quality and repeatability of 3D printing, “because you always has the same flow.” If there are deviations in your filament, these will be controlled and compensated for.”

The Qu4-HT filament quality assurance system. Photo by 3D Printing Industry.

The Qu4-HT filament quality assurance system. Photo by 3D Printing Industry.

Technical specifications

| Maximum print volume | 400x400x360mm |

| materials | All thermoplastics can be extruded below 490 °C |

| Filament diameter (maximum spool size: ∅300 x 100 mm) | 1.75mm (+/- 0.05) |

| Layer thickness | Recommended: 0.15-0.35mm |

| resolution | XY axis < 8µm – Z axis < 8µm |

| Nozzle temperature | Maximum 490℃ |

| Heated print bed | Maximum 250℃ |

| Pressure chamber temperature | Maximum 300℃ |

| Ambient temperature | 18℃ – 26℃ |

| Input voltage (AC) | Three phase – 16A |

| Power supplies (DC) | 24V – 30A |

Subscribe to the 3D Printing Industry newsletter to stay up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page and subscribe to the 3D Printing Industry YouTube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available positions and boost your career.

The featured image shows Qualup’s new Qu4-HT 3D printer at Formnext 2023. Photo by 3D Printing Industry.