Time is running out! Nominate now for the 3D Printing Industry Awards 2023.

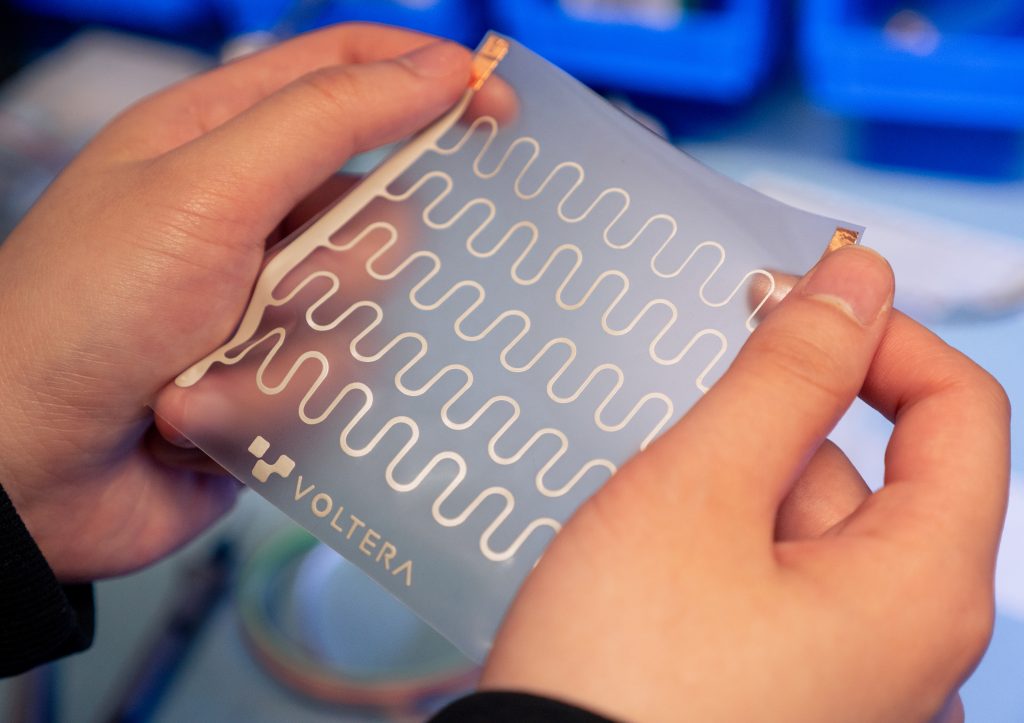

Ontario-based electronics 3D printer maker Voltera’s NOVA was the world’s first 3D printer for soft, stretchable electronics when it was launched last year.

Using DIW (Direct Ink Write) technology, the NOVA can 3D print electronic circuits on soft, stretchy and conformable surfaces.

Voltera claims that the 3D printer’s precision extrusion technology makes conducting electronics research easier and faster and “develops the products of the future” by enabling rapid iterations on the table. This is intended to reduce production costs, shorten development times and achieve more reliable results.

“This first-of-its-kind benchtop machine enables fast, flexible hybrid electronics prototyping and the ability to experiment with custom inks and a variety of substrates,” commented Alroy Almeida, CEO and co-founder of Voltera.

“NOVA is already being used to innovate the way humanity explores space, to develop printed sensors on the skin for medical imaging, and to make prototypes of clothing that can measure your heart rate but still You can use the gentle cycle in your washing machine.”

“NOVA allows us to make devices and align them to sub-10 micron precision, which is critical to everything we do,” added Alex Kashkin, Graduate Researcher, Velasquez Group at MIT. Kashkin is using NOVA to develop 3D printed electron sources to neutralize ionic thruster plumes in low Earth orbit.

“If there is a deviation of 20 micrometers, our devices will explode. We need a lot of precision, we need coordinated materials and NOVA enables both.”

The NOVA 3D printer from Voltera. Photo via Voltera. Photo via Business Wire.

Main features of the NOVA

According to James Pickard, product director at Voltera, NOVA was developed to alleviate the problems associated with prototyping flexible hybrid electronics (FHE).

Pickard highlighted that traditional electrical devices are developed using the standard manufacturing processes and materials used for printed circuit boards (PCBs). This etching process uses dangerous chemicals and is optimized for materials such as FR4 or Kapton with copper to connect silicone components.

However, according to Pickard, traditional electrical manufacturing is limited to a few material options, with limitations in form and functionality. This has led to a growing demand for FHEs that are “soft, stretchy, large format and integrated.”

In order to meet this requirement, the NOVA offers extensive material compatibility. The NOVA has been optimized for screen printing inks, allowing for easier scaling from a lab environment to production. The NOVA also offers a semi-automatic calibration process that allows users to fill the 3D printer’s Smart Dispenser cartridge with the desired material and begin 3D printing within minutes.

The NOVA enables 3D printing of these materials onto a range of substrates. Rigid substrates such as glass, circuit boards and ceramics are all compatible with the NOVA, as are flexible polyimides and PETs, stretchable TPUs and porous substrates such as paper.

Thanks to the NOVA’s quickly interchangeable workspace, these substrates can be easily positioned and prepared for 3D printing. Flexible substrates can be mounted using NOVA’s vacuum table module, while custom fixtures can be used when mounting rigid substrates. A threaded mounting grille is also available and can be customized and adjusted to suit the user’s needs.

Screen printable materials come in a wide range of viscosities and can have numerous rheological properties. These properties can also be affected by temperature, which can create challenges with microdosing.

To alleviate these challenges, the NOVA features a closed-loop pressure measurement system, with a heater also integrated into the 3D printer’s smart dispenser. This is intended to enable a higher level of consistency and control throughout the 3D printing process. Users can also create and save dispensing profiles, making it easier to 3D print with a variety of materials.

The NOVA can also perform 3D printing with a resolution of just 17 µm/pixel. This capability is attributed to the NOVA’s downward vision system, which allows for precise alignment/registration with an AR overlay. This is intended to enable high-quality inspection, alignment and measurement functions.

“I think this type of technology, NOVA, will shine in applications that weren’t possible before. You should not fight or try to compete with silicon chips or circuit boards. “You should try to do something that is impossible with these technologies,” explained Gerd Grau, director of the Electronics Additive Manufacturing Lab at York University. Grau is using the NOVA to develop biomedical tattoo electrodes on the skin.

Technical specifications and prices

Potential customers can contact Voltera’s sales team for pricing information.

| Dosing technology | Direct Ink Writing (DIW) |

| Dimensions | 675mm x 605mm x 345mm |

| Pressure control | Closed circle |

| Control of material temperature | Up to 40℃ |

| 3D printing area | 220mm x 300mm |

| XYZ resolution | 2.5µm x 7µm x 1.25µm |

| Subsurface thickness | Up to 30mm2 |

| Substrates | Rigid: circuit boards, glass, ceramics, etc. Flexible: Polyimide, PET etc. Stretchable: TPU etc. Porous: paper |

| Syringe capacity | Up to 2.5ml |

| Dispensable materials | Included: solder paste, conductor 3, screen printing materials |

| interface | Internet application |

| File formats | Tanner |

| Connectivity | 1x USB-A 2.0, 1x USB-A 3.0, Ethernet, WLAN |

Subscribe to the 3D Printing Industry newsletter to stay up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page and subscribe to the 3D Printing Industry YouTube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available positions and boost your career.