(as of Sep 24, 2025 16:50:18 UTC – Details)

<

Product description

Product Dimensions : 4 x 4 x 11 inches; 2.65 Pounds

Item model number : 3d printer resin-5512

Date First Available : June 20, 2025

Manufacturer : Cretbee

ASIN : B0FDVTMYD7

Best Sellers Rank: #489,015 in Industrial & Scientific (See Top 100 in Industrial & Scientific) #389 in 3D Printing Liquid

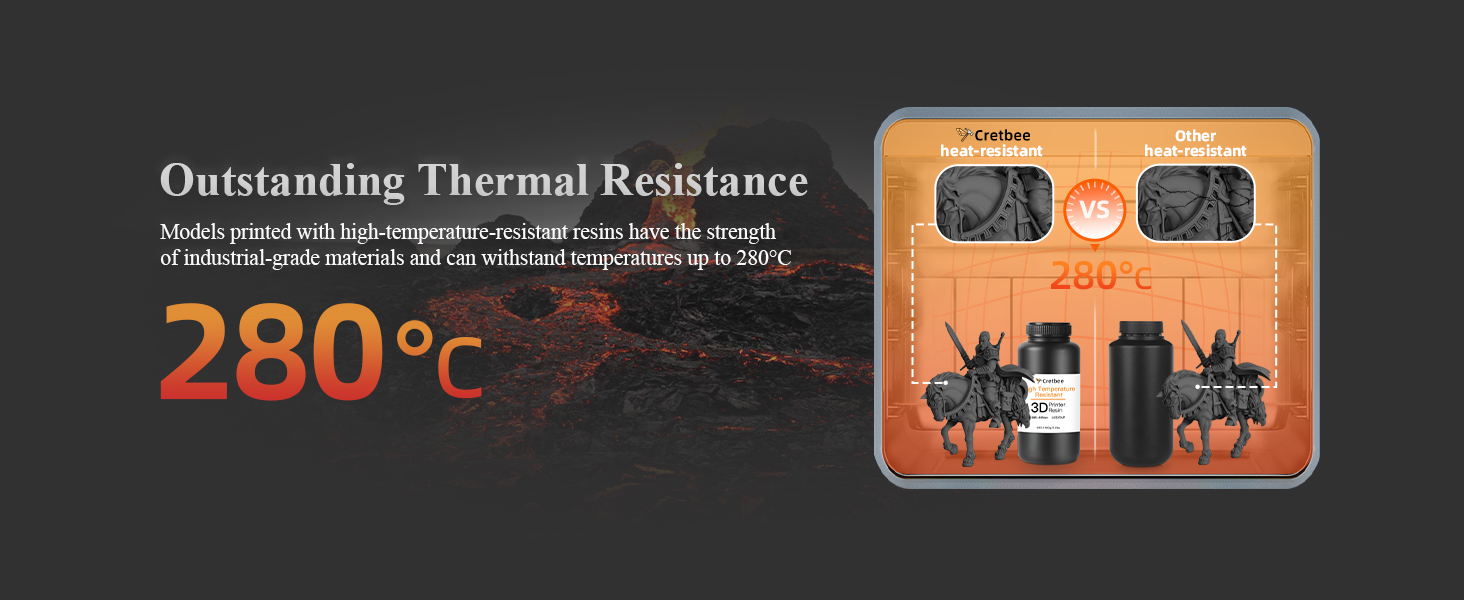

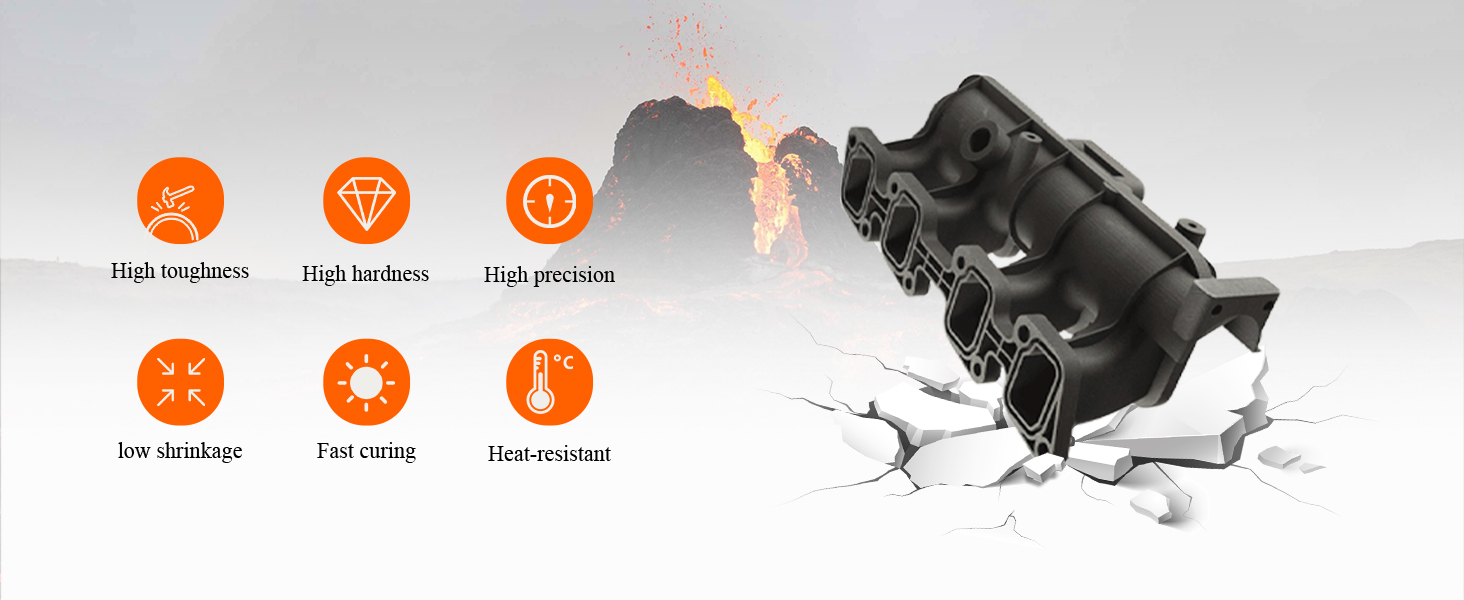

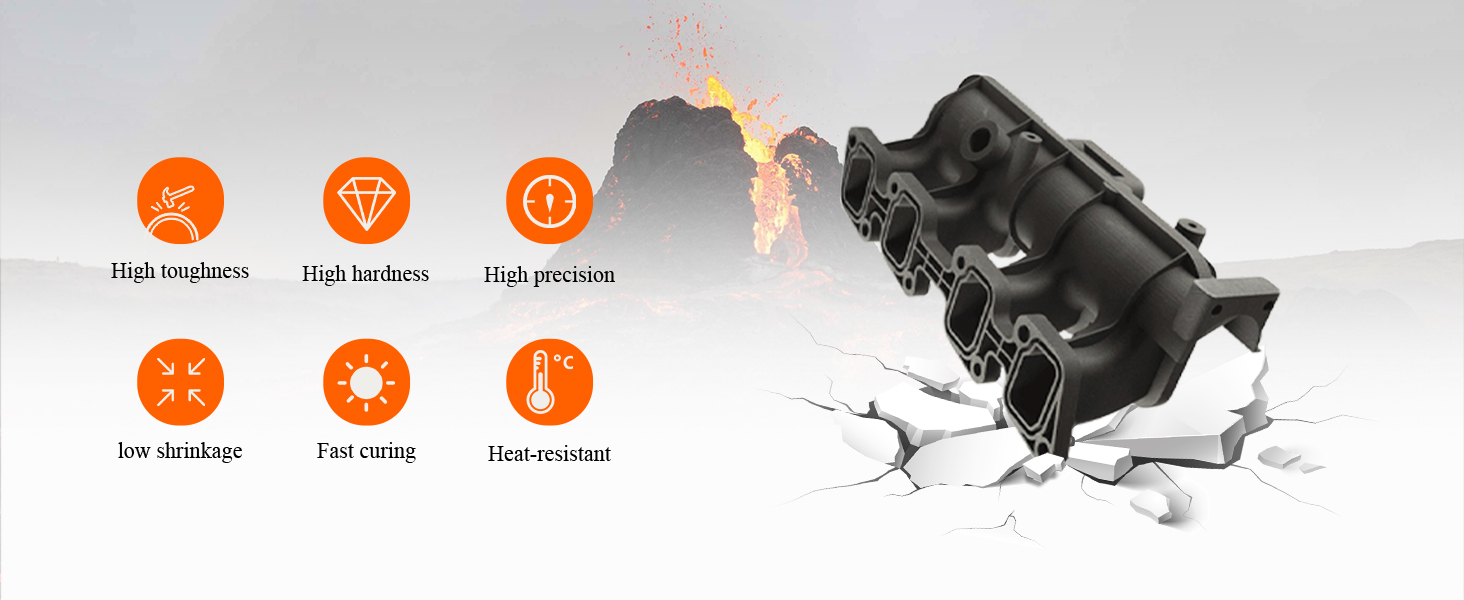

Excellent Heat Resistance & High Stability: Cretbee high temperature resistant resins can be used in high temperature environments up to 280℃ without softening. Long time in 200 ℃ high temperature with 55% humidity under extreme conditions of continuous baking, but still can maintain no cracking, no deformation. The material has a high degree of stability of molded products, especially suitable for harsh high-temperature environment, is the ideal solution for high-temperature manufacturing process

Rapid Molding & Low Shrinkage: Cretbee 3d printing resin has high reactivity, 0.05mm exposure time of only 2-3 seconds (under 4000-5000 mW/cm² light intensity), to achieve rapid molding. Extremely low volumetric shrinkage after hardening ensures a smooth enough print surface

High Precision & Simplified Post-Processing: Models printed with Cretbee’s high-temperature-resistant resins show ultra-smooth surfaces and distinctive color textures, with excellent resolution and detail reproduction, effectively reducing post-processing procedures and improving overall production efficiency

Wide Range of Applications: Cretbee high-temperature-resistant 3D resin can be used in industrial manufacturing and creative development in many fields, including injection molds, vacuum molding and other scenarios. Compatible with mainstream DLP/LCD printing equipment, optimized formula for small batch production to meet diversified needs

Note: Due to the material properties, the resin will slowly crystallize when the temperature is lower than 20℃, it needs to be heated up to 60℃ before use until the resin returns to the liquid state, and then cooled down to within 30℃ before use; it needs to be coated with a release agent for the product molding area and runners before use in the printing mold, so that it is convenient to remove the product

![phrozen 3D Printer Rapid Resin [RPG], Low Shrinkage Superior Precision Smooth Surface Finish, 405nm LCD UV-Curing Photopolymer Resin, Beige (1KG)](https://i0.wp.com/3dprintingzoom.com/wp-content/uploads/2025/09/phrozen-3D-Printer-Rapid-Resin-RPG-Low-Shrinkage-Superior-Precision.jpg?resize=300%2C300&ssl=1)