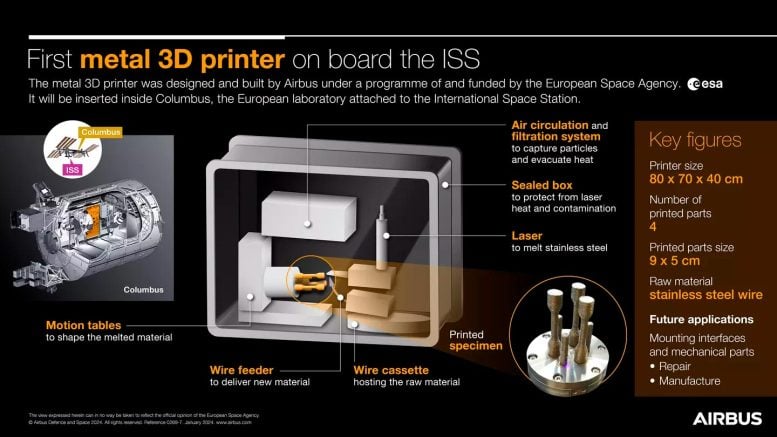

A groundbreaking European-made metal 3D printer has been brought to the International Space Station, marking the first time metal 3D printing has been carried out in orbit. This initiative, leveraging a collaboration between ESA and Airbus, aims to demonstrate the potential of manufacturing in space. Photo credit: Airbus Defense and Space SAS

3D metal printing will soon take place in orbit for the first time. A groundbreaking European-made metal 3D printer is on the way

” data-gt-translate-attributes=”[{“attribute”:”data-cmtooltip”, “format”:”html”}]” tabindex=”0″ role=”link”>International Space Station (ISS) on the Cygnus NG-20 resupply mission that launched this week.

“This new 3D printer, which prints metal parts, represents a world first at a time of growing interest in manufacturing in space,” explains Rob Postema, ESA’s technical director. “Polymer-based 3D printers have already been brought to the ISS and used there. It uses plastic material that is heated at the head of the printer and then applied to build up the desired object layer by layer.

“Metal 3D printing is more technically challenging because it requires much higher temperatures and uses a laser to melt metal. The safety of the crew and the station itself must be guaranteed – but at the same time the maintenance options are very limited. If successful, the strength, conductivity and rigidity of metal would take the potential of 3D printing in space to new levels.”

The first metal 3D printer used aboard the International Space Station has been seen during ground tests, producing a sample part of ESA’s design. With its ESA-led development, this metal 3D printer aims to prove that metal 3D printing can be carried out in weightless conditions and pave the way for a future production possibility in space, where astronauts can provide any tools or spare parts they need far from Earth can produce. Photo credit: Airbus Defense and Space SAS

Printing in space

The Cygnus NG-20 spacecraft, carrying the metal 3D printer and 8,200 pounds of scientific research and cargo, docked with the International Space Station on February 1. Once unpacked, ESA astronaut Andreas Mogensen will prepare and install the approximately 180 kg metal 3D printer in the European Draw Rack Mark II in ESA’s Columbus module. Once installed, the printer will be controlled and monitored from Earth, allowing printing to occur without Andreas’ supervision.

The metal 3D printer technology demonstrator was developed by an industrial team led by Airbus Defense and Space SAS – which is also co-funding the project – on behalf of ESA’s Manned and Robotic Exploration Directorate.

“This in-orbit demonstration is the result of close collaboration between ESA and Airbus’ small, dynamic engineering team,” comments Patrick Crescent, Project Manager at Airbus. “But this is not just a step into the future; It is a leap in innovation in space exploration. It paves the way for the production of more complex metallic structures in space. This is a crucial advantage for securing lunar exploration

” data-gt-translate-attributes=”[{“attribute”:”data-cmtooltip”, “format”:”html”}]” tabindex=”0″ role=”link”>Mars.”

Photo credit: Airbus

The printer prints with a stainless steel type commonly used for medical implants and water treatment due to its good corrosion resistance.

The stainless steel wire is fed into the printing area, which is heated by a high-power laser that is about a million times more powerful than your average laser pointer. As the wire dips into the molten pool, the end of the wire melts and metal is then added to the print.

ESA materials engineer Advenit Makaya from ESA’s Technology, Engineering and Quality Directorate provided technical support for the project: “The melt pool of the printing process is very small, on the order of a millimeter in diameter, so the surface tension of the liquid metal drops.” holds it securely in place in weightlessness. Still, the melting point of stainless steel is around 1400°C, so the printer operates in a completely sealed enclosure, preventing excess heat or fumes from reaching the space station crew. And before printing begins, the printer’s internal oxygen atmosphere must be vented into space and replaced with nitrogen – the hot stainless steel would oxidize if exposed to the oxygen.”

The metal 3D printer will be the first time a 3D printer will print in metal on the International Space Station. ESA commissioned Airbus Defense and Space SAS to produce the 3D printer. It will feature a stainless steel wire that is melted using a high-power laser and will print four prints, each taking two to four weeks to print.

The launch took place on January 30, 2024 with NG-20. Photo credit: Airbus Defense and Space SAS

Shapes and sizes

Four interesting shapes were selected to test the performance of the metal 3D printer. These initial objects will be compared to the same shapes printed on the ground, called reference prints, to see how the space environment affects the printing process. The four prints are all smaller than a soda can, weigh less than 250g per print and take approximately two to four weeks to print. Due to noise regulations on the space station, scheduled printing time is limited to four hours per day – the printer’s fans and motor are relatively loud.

Once a mold has been printed, Andreas removes it from the printer and packages it to return safely to Earth for processing and analysis to understand the differences in print quality and performance in space and on Earth.

A reference and a 0xg print, part of a special tool, will go to the European Astronaut Center (EAC) in Cologne, Germany. Two more are headed to ESA’s technical heartland, the European Space Research and Technology Center (ESTEC), where a team in the Materials and Electrical Components Laboratory awaits samples for macro and micro analysis of the printed parts. The final print will go to the Technical University of Denmark (DTU), which proposed its shape and will study its thermal properties to aid in future antenna alignment, for example.

Preparing for the future

“As a technology demonstration project, our goal is to prove the potential of metal 3D printing in space,” adds Rob. “We have learned a lot so far and hope to learn much more to make manufacturing and assembly in space a practical proposition.”

One of ESA’s goals for future development is to create a circular economy in space and recycle materials in orbit to enable better use of resources. One possibility would be to convert parts of old satellites into new tools or structures. The 3D printer would eliminate the need to send a tool up on a rocket and allow astronauts to print the parts they need in orbit.

Tommaso Ghidini, Head of ESA’s Mechanical Division, notes: “Metal 3D in space printing is a promising opportunity to support future exploration activities, but also beyond to more sustainable space activities through in-situ manufacturing, repair and perhaps beyond to contribute.” Recycling space structures for a wide range of applications. This includes the manufacture and assembly of large infrastructures in orbit as well as the long-term colonization of the planet by humans. These aspects are key focuses of ESA’s upcoming cross-technology initiatives.”

Thomas Rohr, Head of ESA’s Materials and Processes Division, added: “This technology demonstration, demonstrating the processing of metallic materials in microgravity, paves the way for future efforts to produce infrastructure beyond Earth’s boundaries.”